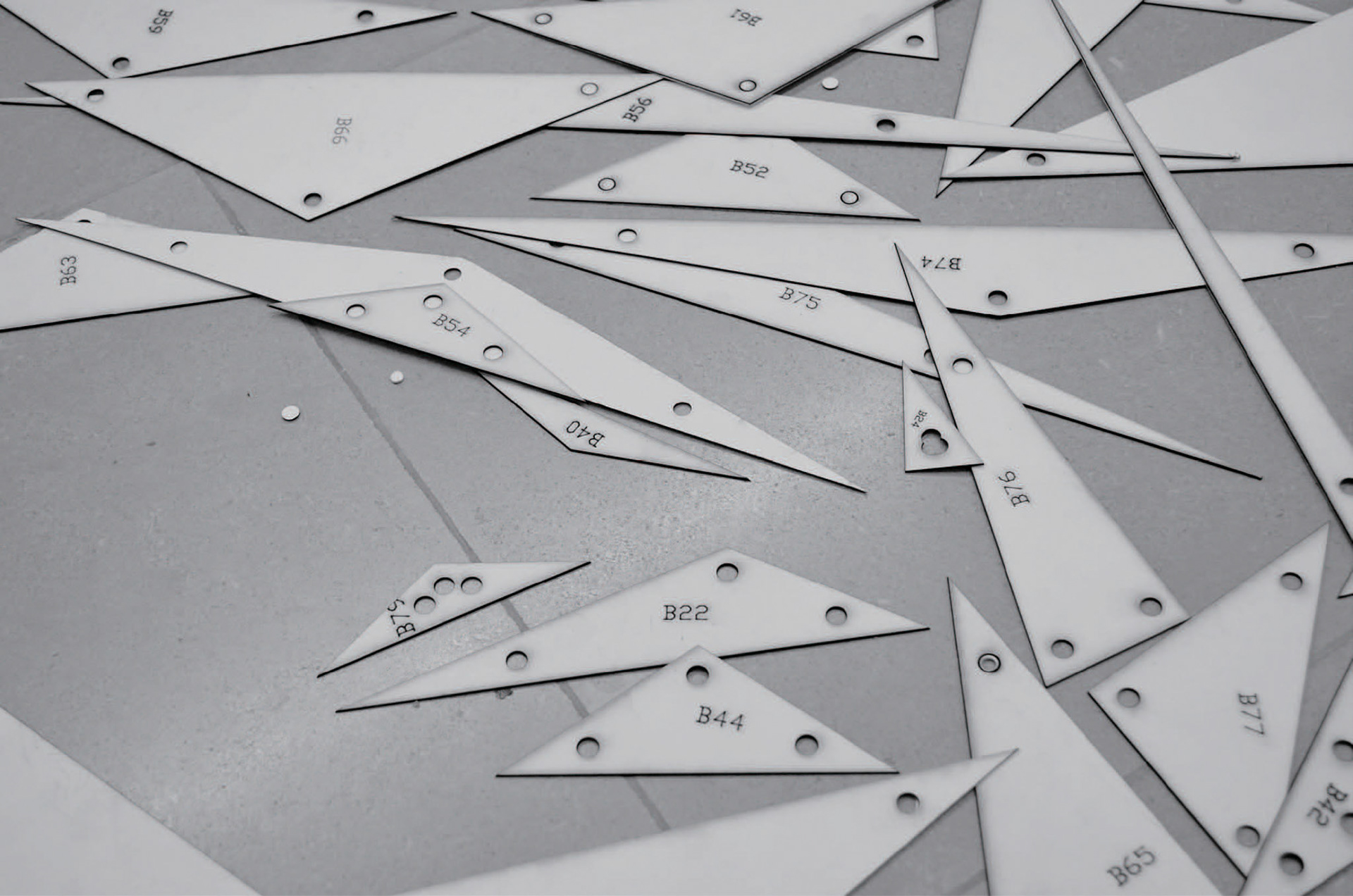

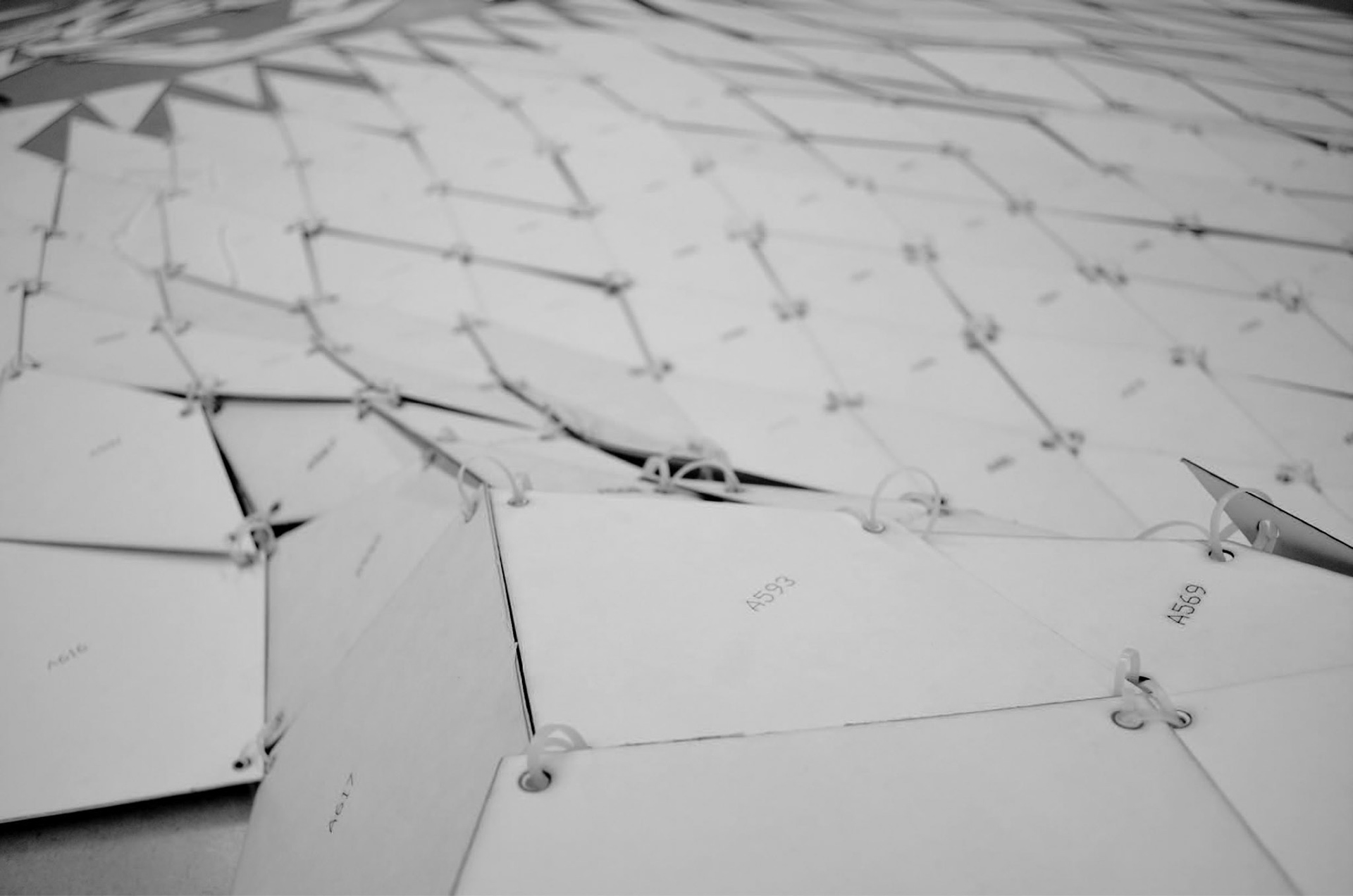

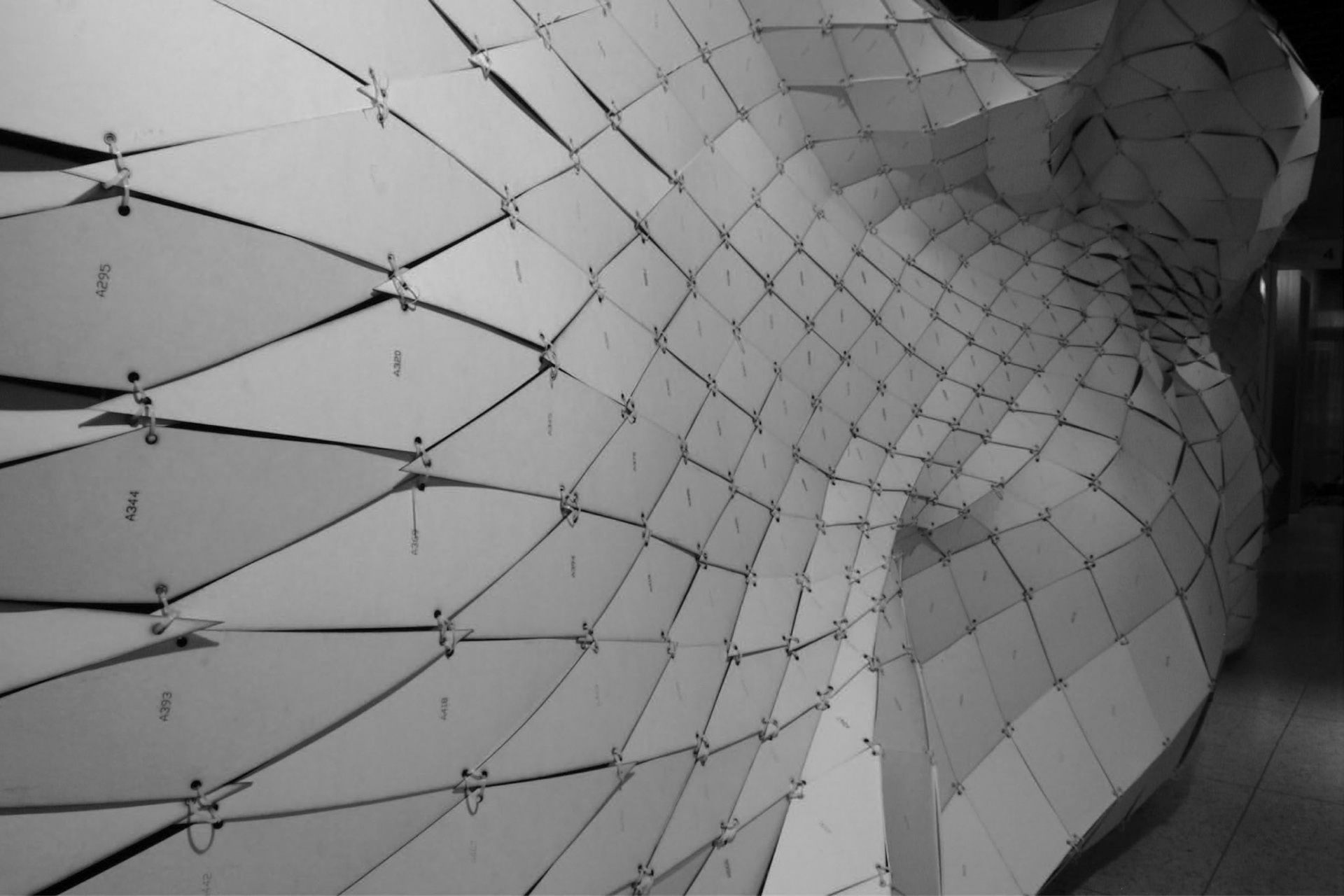

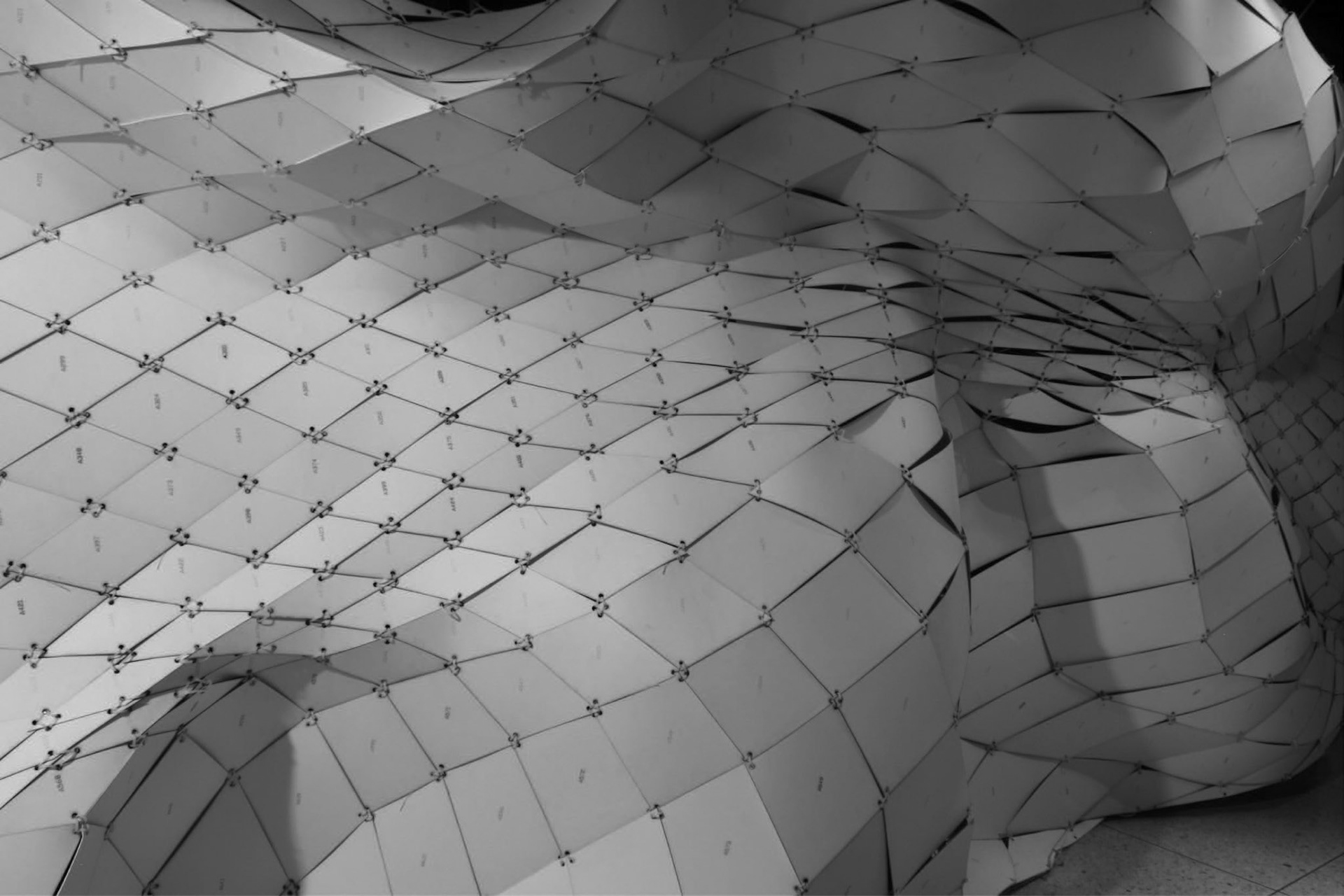

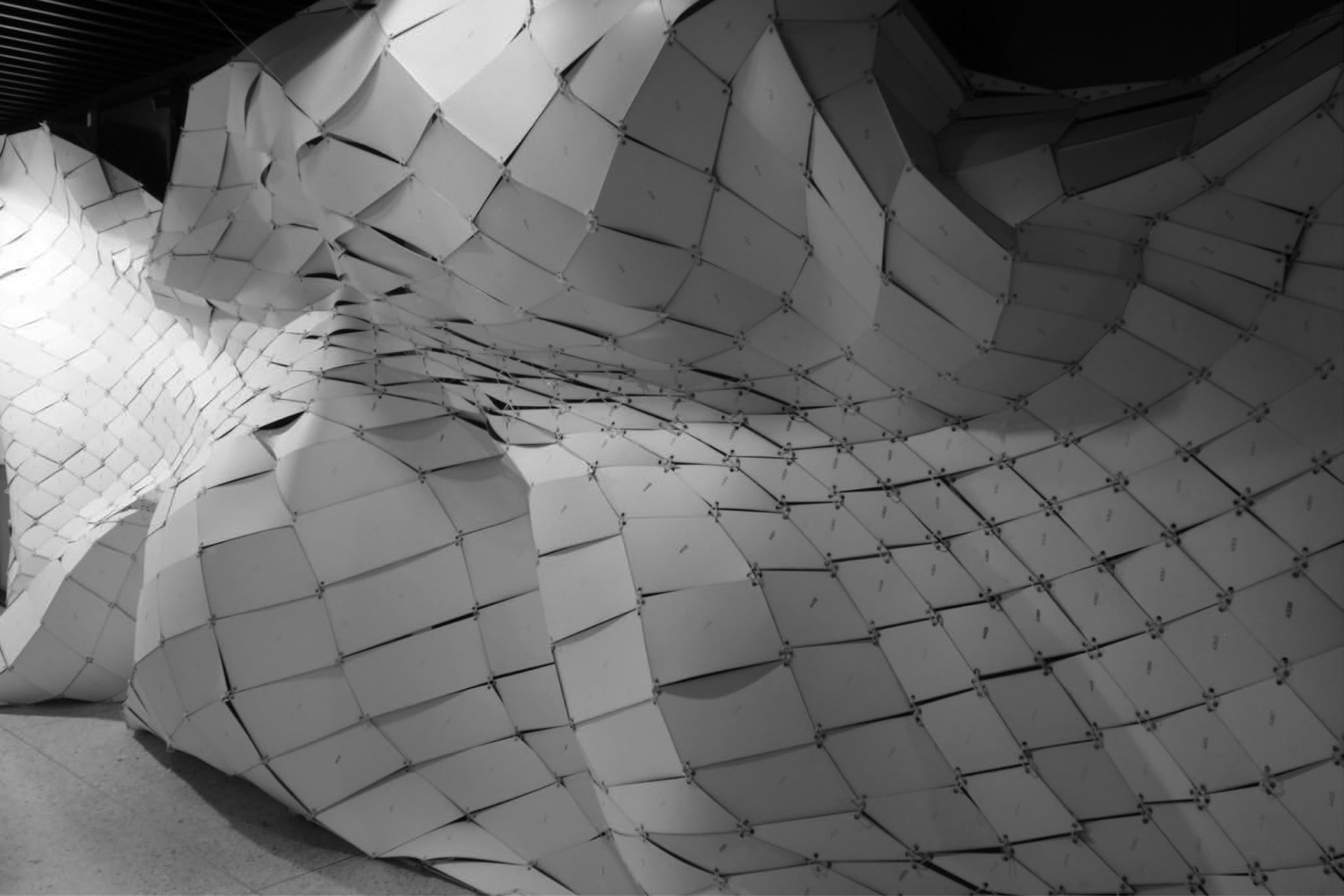

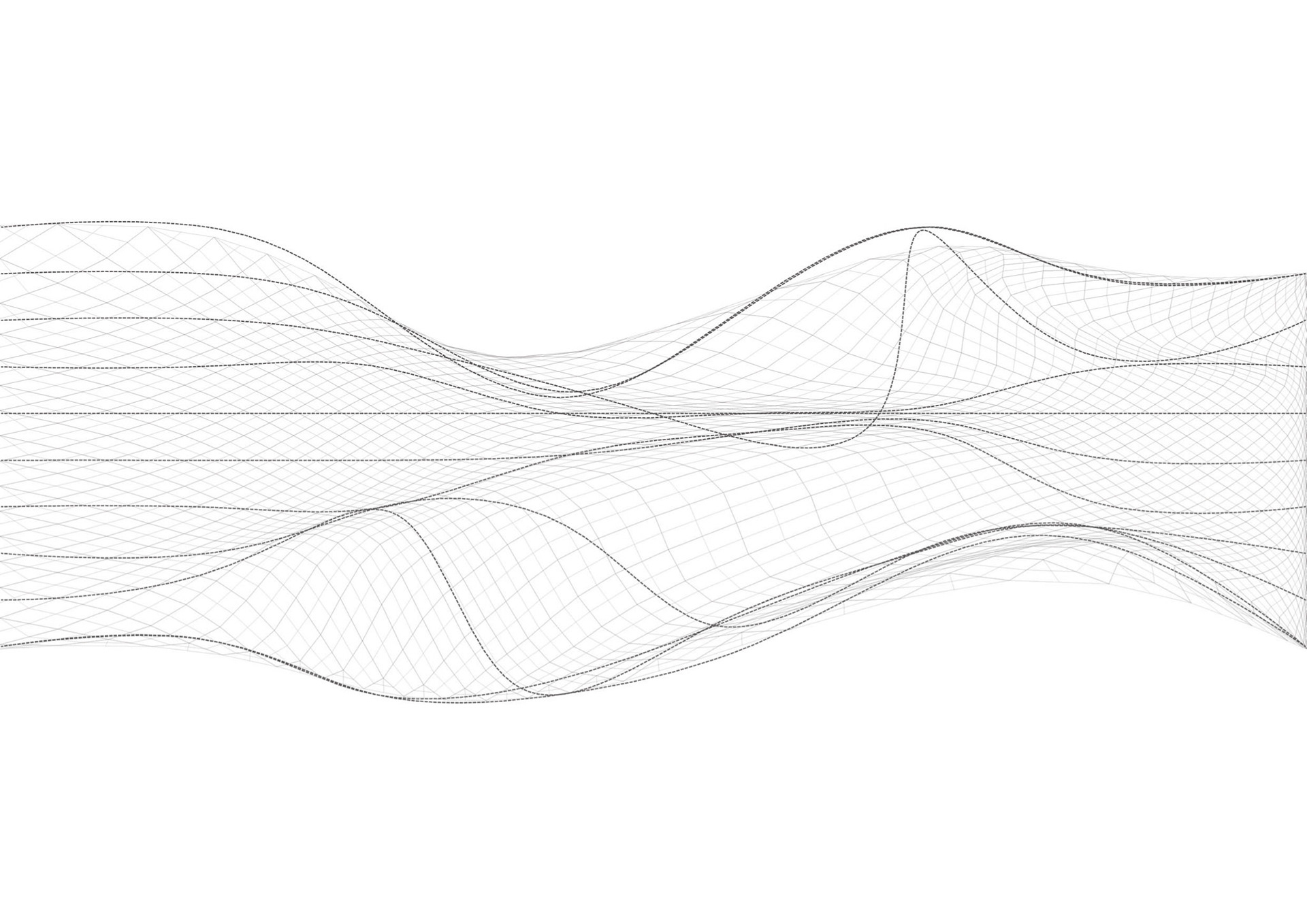

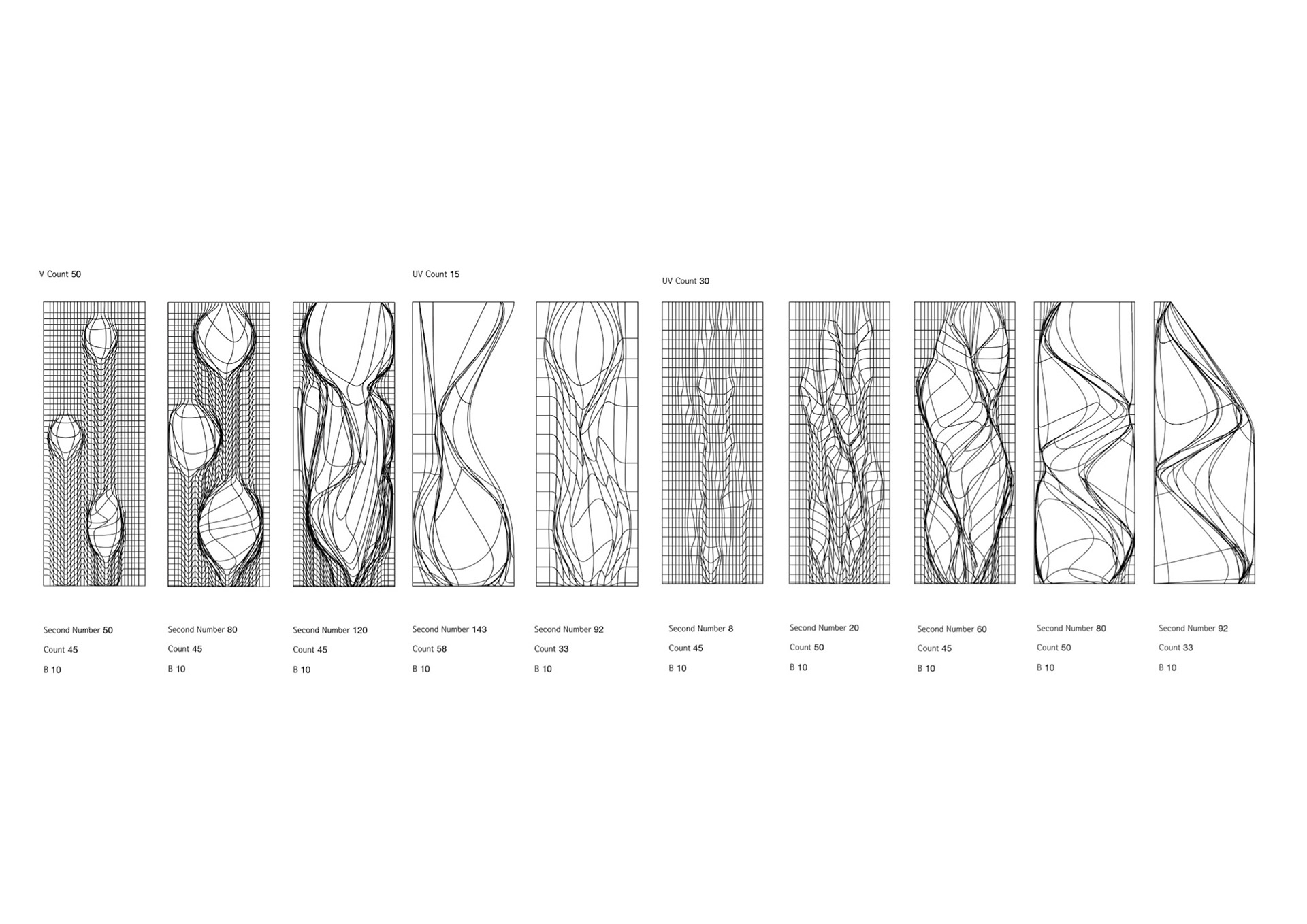

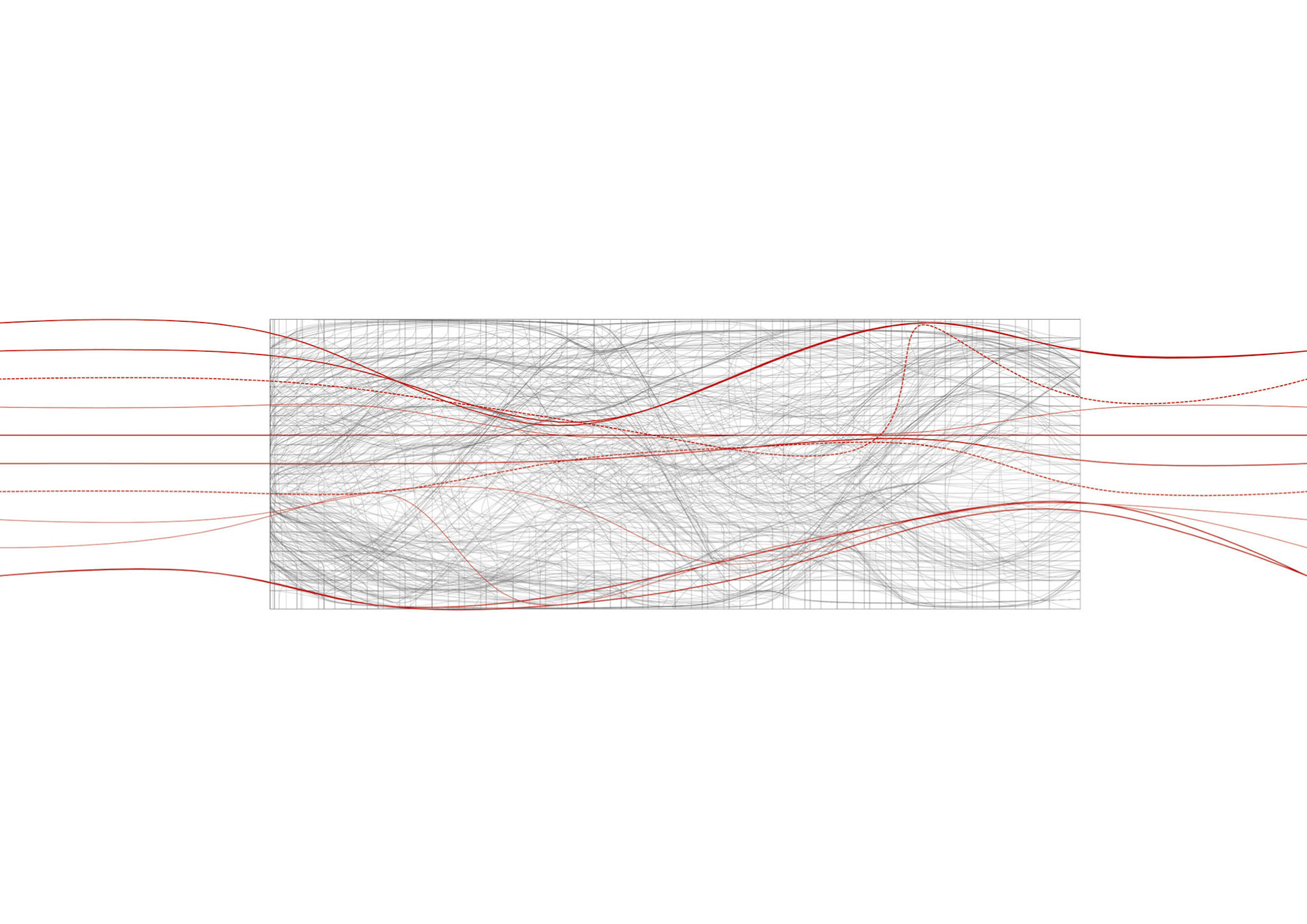

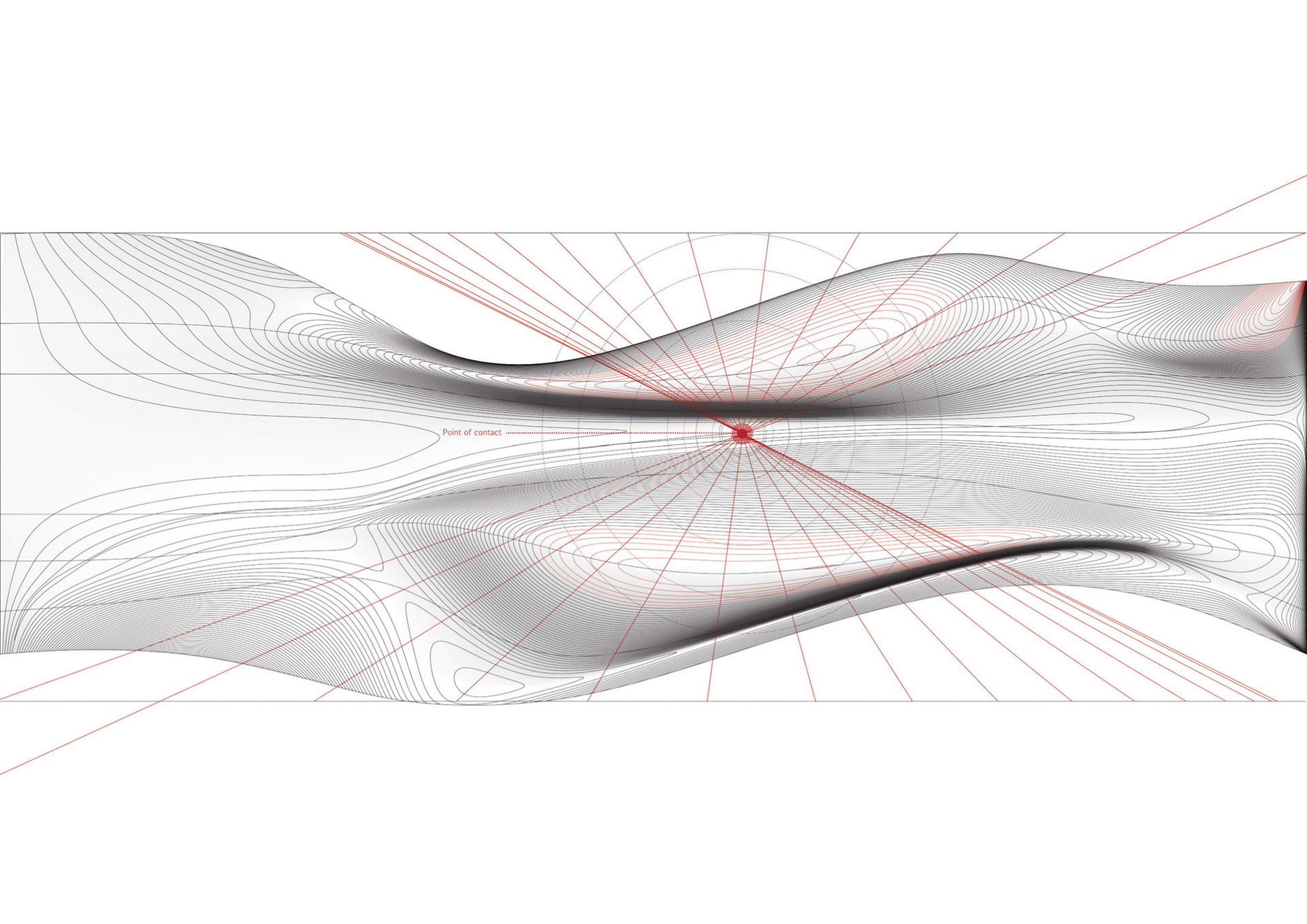

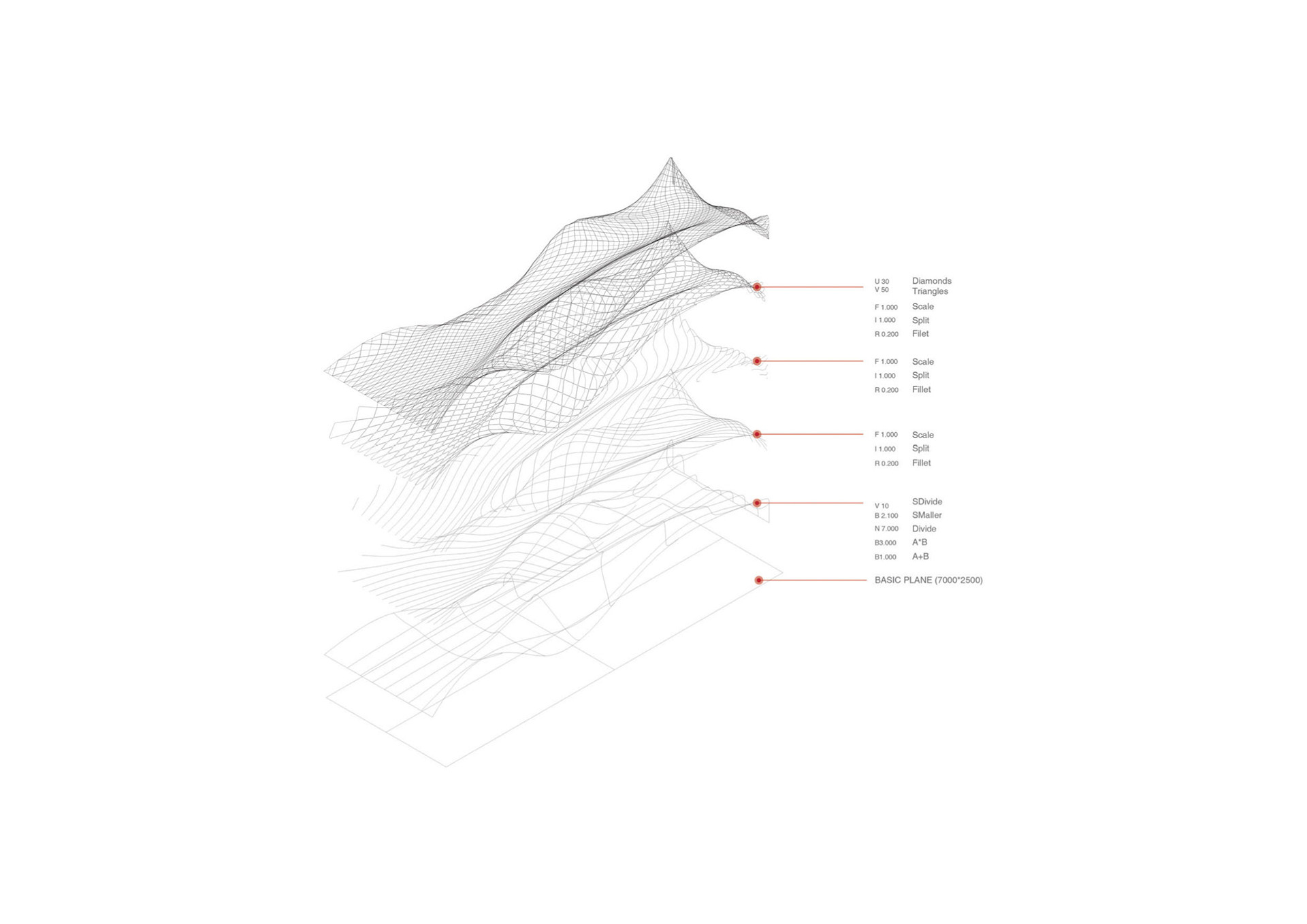

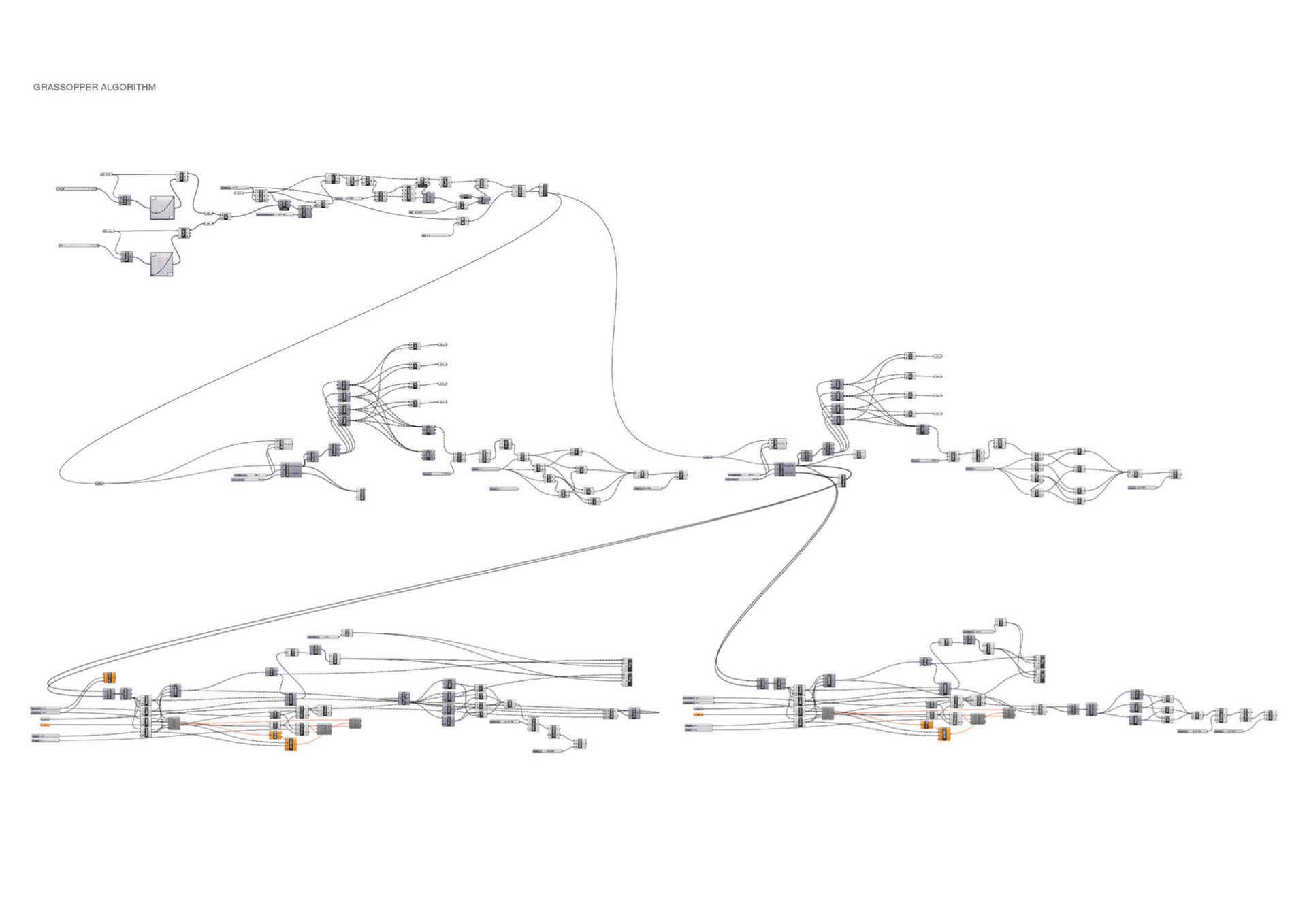

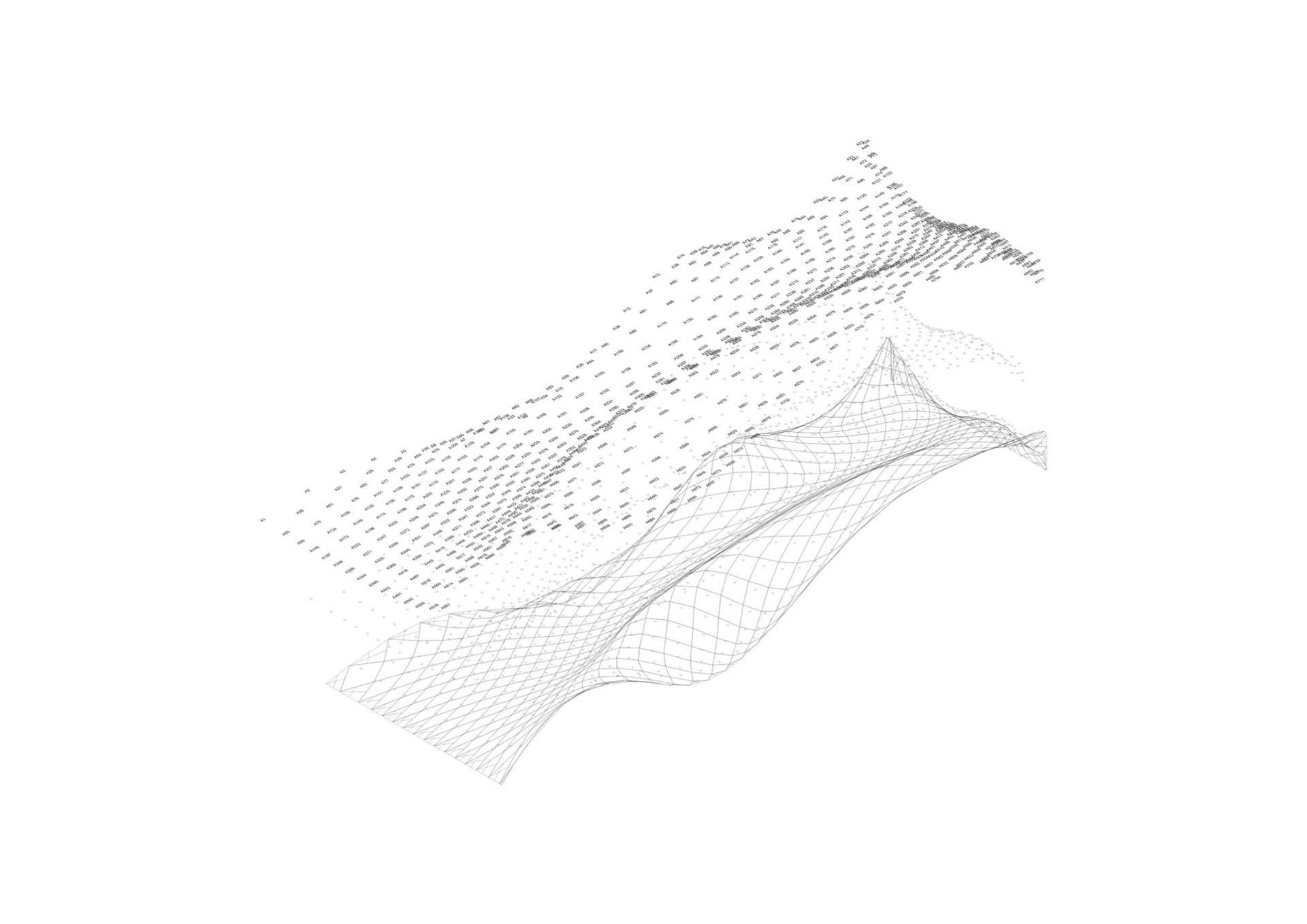

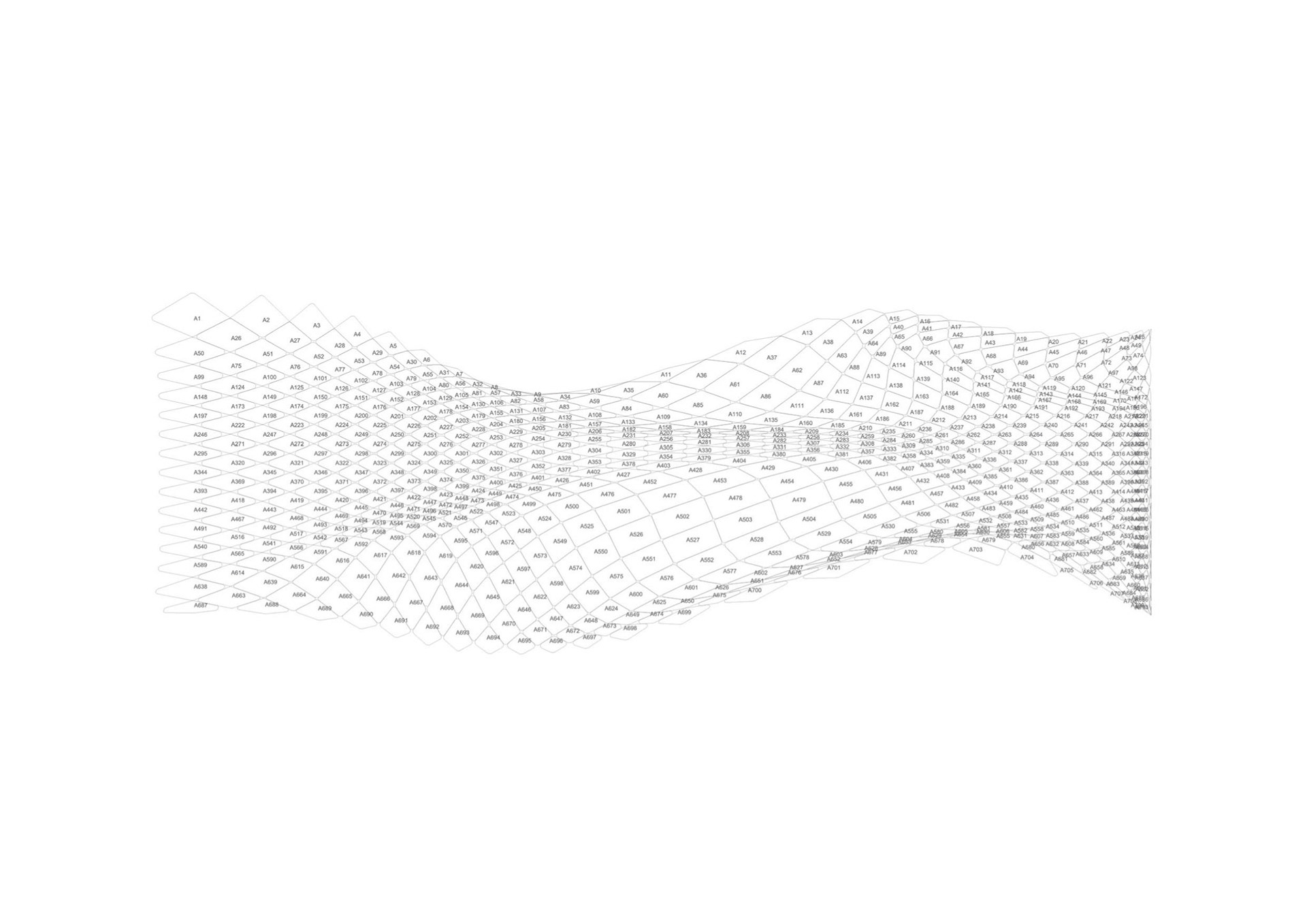

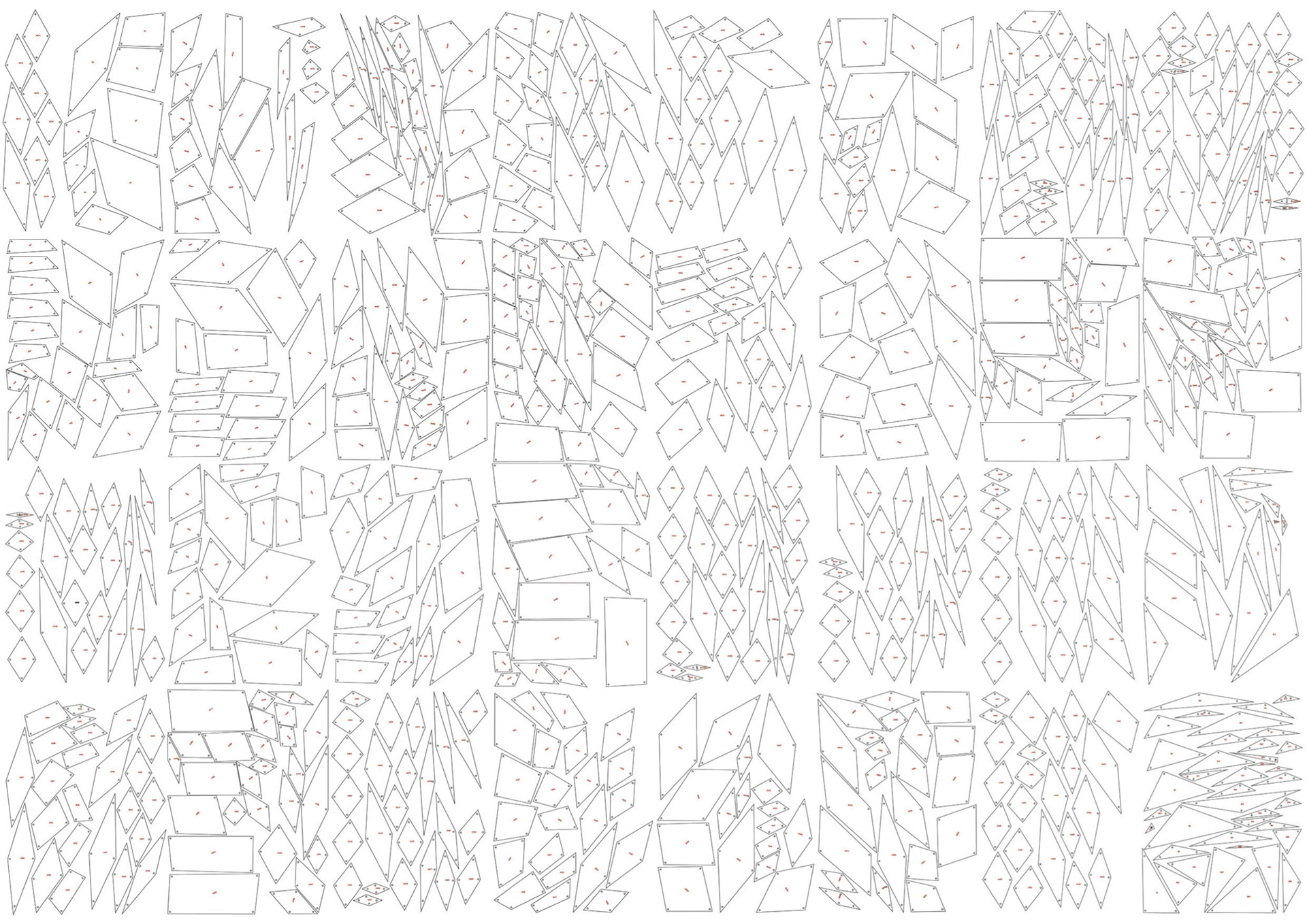

As a method to realize the curved surface in the course of deriving the 3- NURBS surface, diamond paneling type was used. Simulation of the results based on the UV count and the density of the panel allowed for simultaneous consideration of fabrication material and installation type. In fabrication process that experienced intensive process construction or product production process, model paper and cable tie laser cutting were used in consideration of reasonable price and processing method, and total 1000 modules were cut and reassembled by 7 people. Through the process, we were able to complete one form. For the concrete installation, we designed the structure to withstand the load and calculated the predicted error of the fabricated modules, and decided the material and the coupling type, and divided into 7 parts in total and finished in one form, were selected. In this process, we were able to gauge the total budget and the working time.